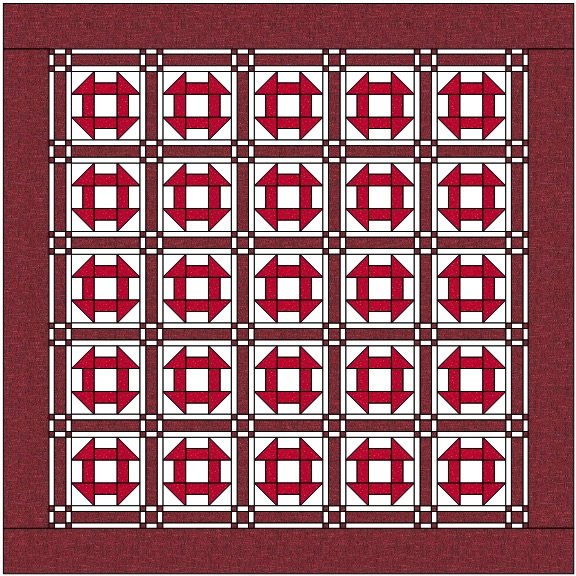

Churn Dash Sashing and Cornerstones

Yesterday did not go as planned because I spent the entire morning trying to straighten out an e-mail issue while dealing with a snarky tech support person. I managed to solve the problem without his help (or snark), but it wasn’t what I had planned to do when I woke up. And I think those two e-mail addresses are going to go away after this billing cycle ends. I’m done with that company.

[I don’t have much tolerance for people whose preferred method of communication is snark or sarcasm. Learn to communicate like an adult, not a 14-year-old.]

I was so irritated that it took a bit of effort after that to get myself back on track. I pressed a few lengths of fabric and watched the latest A Quilting Life podcast on YouTube. After lunch, I wrote up the class handout for tomorrow’s T-shirt class and started gathering my supplies together.

I also worked on the sashing for the Churn Dash quilt. I hadn’t intended for that quilt to shoot to the top of the queue, but both it and the Sunbonnet Sue quilt will have the same kind of sashing design. I would rather get comfortable with making the sashing and working the bugs out on the Churn Dash quilt, first.

Electric Quilt 8 has many features that streamline the work associated with making a quilt. It will tell you how much yardage of each fabric you need. It will spit out rotary-cutting instructions. It will create and print templates if you need them. However, it cannot factor in the many different tricks and shortcuts for making blocks, like making slightly oversized units and trimming them down after sewing. All of the instructions it generates assume that you will cut each individual piece exactly to size and sew it together perfectly.

This is the proposed layout for those Churn Dash blocks.

The sashing is made up of three narrow strips sewn together. The cornerstones are an inverse of the sashing strips. The teeny-tiny blocks in those cornerstones measure 1-1/4” before they are sewn together. In no universe would I be able to sew together anything that small and have it come out the correct size. My plan was to sew the narrow strips together, first, then cut them into smaller units and sew the units together. EQ8 only gave me the dimensions of each (tiny) unit, so I had to translate that into a strip and then figure out what size pieces I needed to cut from each strip.

Strip sewing is one place where I really appreciate the Accufeed system on my Janome sewing machine. Most sewing machines are engineered such that the feed dogs feed the bottom piece of fabric at a slightly faster rate than the top piece of fabric. That’s useful when you want to ease in one of the fabrics, but it can wreak havoc when sewing strips together. They end up being twisted and wonky. The Accufeed system—or a walking foot—feeds the fabrics through at the same rate. I put the quarter-inch Accufeed foot on my machine and ran all the strips through. They came out perfectly straight.

This is what the cornerstones look like after sewing the three units together:

I pressed the seams open on the back.

I usually press my seams to the side, but in blocks this small (3”), pressing them open does help to reduce bulk. I also used my tailor’s clapper as a seam press to flatten them, a trick I learned from Kimberly Jolly at Fat Quarter Shop.

All 36 cornerstones are made. Now I need to cut the sashing strips to the correct length and sew them to each block.

I’d like to get back to working on that red Candy Coated quilt soon.

********************************************************

In other news, the accountant said he will have the construction company tax returns done this week. I still have to get him what he needs to do our personal returns, but that shouldn’t take long to put together. I’ve also scheduled my trip to Seattle, although the first Airbnb I attempted to reserve required proof of a vaccine passport. I found a different one about five minutes from DD#2.

Our church’s Mennonite Disaster Service group is going to Okanogan, Washington, for a week in March to help out on a project there. One of our members will be there for the entire month of March as a team leader. We don’t send a group every year, but in years past, we’ve had people go to Detroit, Texas, New Orleans, North Carolina, and a few other places.